Packaging printing is under increasing pressure today: rising production speeds, growing quality requirements and constant cost pressure shape everyday operations. In this environment, service and support offerings from machine and system manufacturers are gaining importance. Especially with process-supporting technologies such as corona surface treatment of films on extrusion, printing and laminating machines, it becomes clear that continuous maintenance and support are crucial for process reliability.

Preventive maintenance ensures stable processes

Vetaphone, a supplier of corona surface treatment systems, focuses on a holistic customer service approach. In addition to delivery and installation, the company offers structured maintenance and support programmes designed to ensure reliable system performance over the long term. Corona systems are often regarded as a “run-along” component within production lines. Although modern systems are far more reliable than their predecessors, they still require regular maintenance to prevent performance losses or unplanned downtime.

In an environment where highly automated and capital-intensive systems must be utilised economically, preventive maintenance concepts are a key success factor. Vetaphone therefore offers so-called preventive maintenance contracts. These provide predictable costs, discounted spare parts and technical support either on site or via remote access. The offering is complemented by regular service visits, organised and carried out by trained service specialists.

Flexible concepts for different users

User requirements vary widely: some companies have their own maintenance teams, while others rely on external support. The number of installed systems and the level of in-house technical expertise also differ significantly. Accordingly, the service contracts are modular in design and can be adapted to different usage scenarios – from basic support to regular inspections to ensure performance and operational safety.

For users, the benefits are clear: fewer unplanned machine stoppages, consistent treatment quality, rapid access to expert knowledge and optimised spare parts costs. At the same time, production staff can focus on their core tasks without having to worry about maintenance issues.

Manufacturers also benefit: feedback from day-to-day operation provides valuable insights into frequently occurring issues and supports the continuous development of the technology. In an increasingly complex production environment, such structured service and maintenance concepts make a decisive contribution to securing efficiency, quality and cost-effectiveness in the long term.

How does corona surface treatment of plastic films work?

Corona surface treatment is a physical process primarily used in plastics processing to improve the adhesion properties of films and other plastic surfaces. Typical applications include printing and bonding processes in packaging, labels and flexible films.

Principle of operation:

Plastic films such as polyethylene (PE), polypropylene (PP) or PET naturally have smooth, chemically inert surfaces with poor wettability. During corona treatment, the film is passed through a high-voltage electrical discharge (corona discharge). This creates a plasma of ionised air molecules that chemically activates the plastic surface.

The treatment causes polar functional groups such as hydroxyl or carbonyl groups to form on the surface, increasing surface energy. Higher surface energy means that inks, coatings and adhesives adhere more effectively, without the need for additional chemical substances.

System design and process:

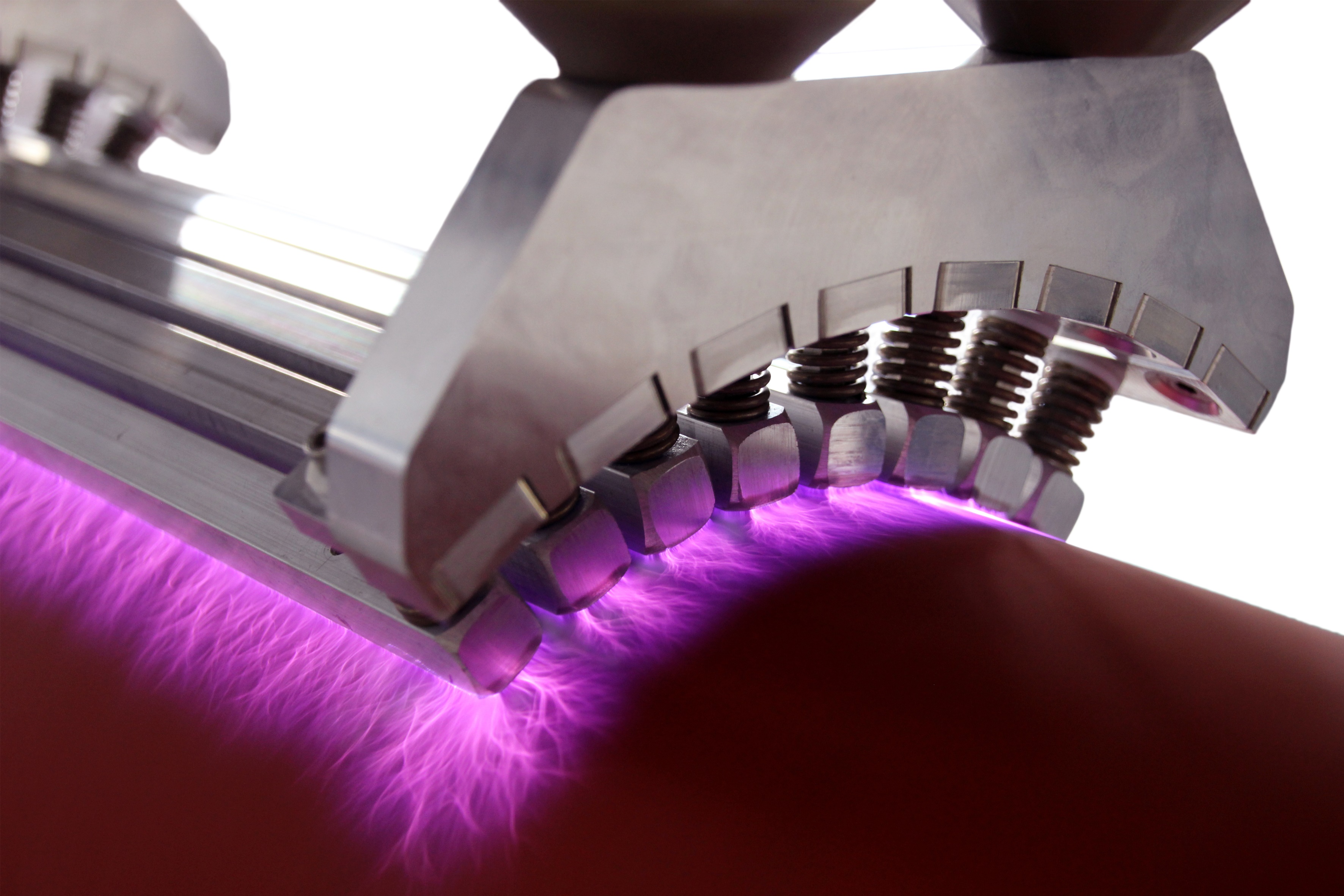

A typical corona treatment system consists of a high-voltage electrode and a counter-electrode, between which the film passes at a controlled speed. Air ionisation occurs in the gap between the electrode and the film, resulting in chemical activation of the surface.

Advantages:

• Improved adhesion of inks, coatings and adhesives

• Inline-capable within the production process

• Environmentally friendly, as no additional chemicals are required

• Fast and targeted surface activation

Limitations:

• Effect limited to the very top surface layer of the film

• Treatment effectiveness decreases with prolonged storage or contamination

• Excessive energy input can cause mechanical damage to the film surface

Corona technology is therefore a well-established and efficient method for preparing plastic films for further processing steps and for sustainably ensuring the quality of printing and bonding applications.